6 photos

1947' Rover P2

Report This Ad!Rate This!Bookmark This

£5,750Published 24 December 2021ID: lYWNrc

Expired

4 years, 1 month ago

4 years, 1 month ago

Information from the owner

Body: Sports Car

Age: 74 years

Exterior color: Bronze

Seller's comments about 1947' Rover P2

Flathead V8 P2 Rat Special Overdrive Project

Project for Sale:

This project consists of what is believed to be a unique powertrain assembly - a 221 cubic inch Ford V8 flathead engine mated to a Jaguar 3. 4 litre overdrive gearbox (circa 1965) - together with a Rover P2 chassis. The chassis is on the DVLA database and the correct VIN plate is available with its original bulkhead. An AutoCad design file of fundamental layout etc is available to those with access to the software. A laser cutting file is available for engine installation, brake/ clutch pedal and other components. A4 prints could also be supplied to assist. A casting pattern for the unique bell-housing is available with the package. The design and engineering work has been carried out by an ex automotive engineer.

The intention has been to provide a character vehicle with the ability to cruise at moderate motorway speeds whilst providing acceptable fuel economy and reasonable refinement for touring. These attributes can be expected from the high-torque eight-cylinder engine, with power delivered through, what is effectively, a five-speed gearbox. See vehicle concept sketches.

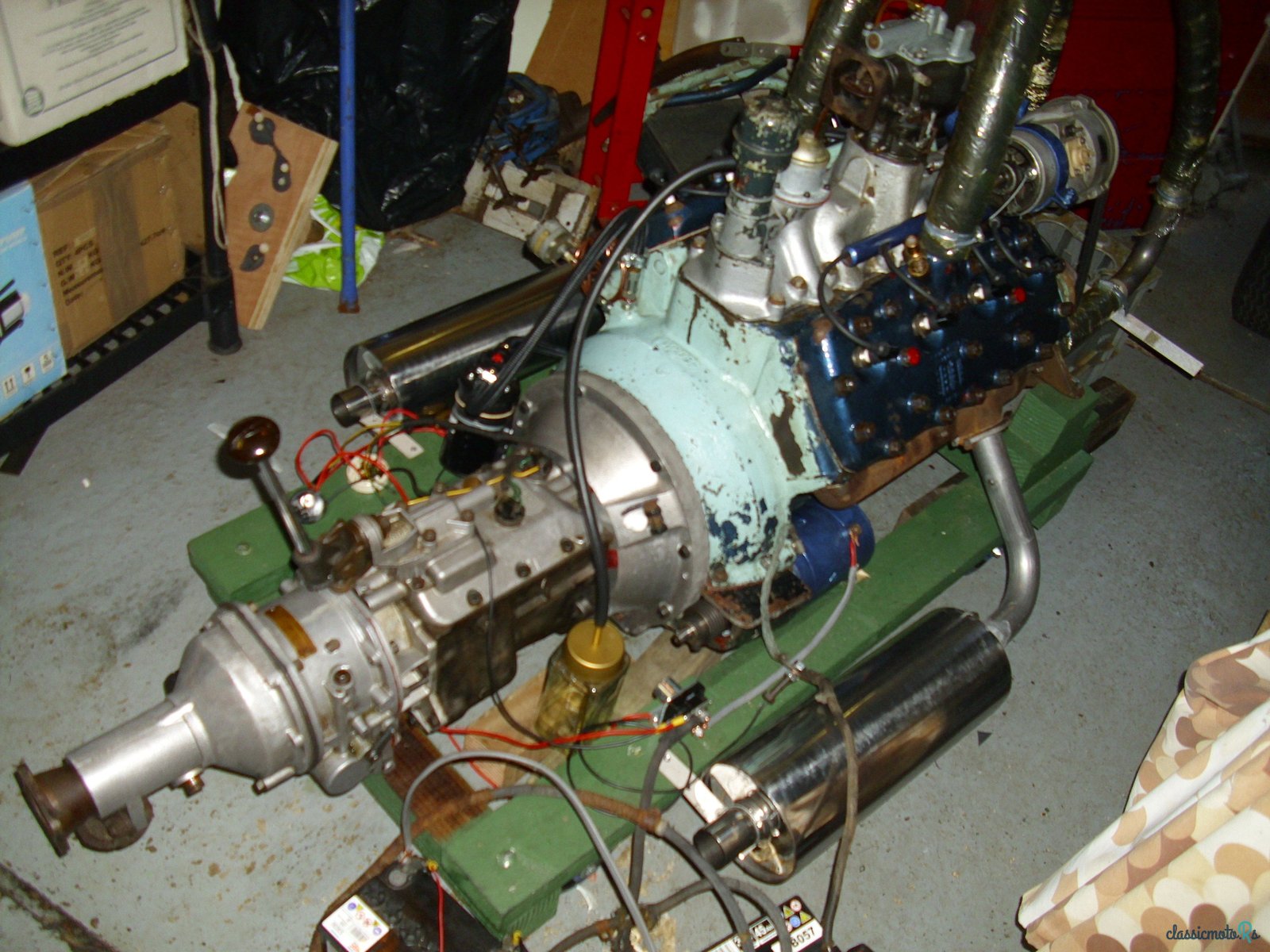

The engine was built to prove out the gearbox installation, for vehicle build and initial use. The original surface patination has been deliberately retained. The engine is assembled from the better parts of two WWII fire pump power units (built at the Dagenham factory). The engine model is typical of the 1937 – 1942 American design but with the earlier 21 stud head and the non-standard big-end journals (as used later in the Ford Pilot). Cylinder liners were standard in these engines and this particular engine has hard-chromed upper piston rings which hardly wear the carbon-rich liners. The pistons have light wear. Crankshaft big-end journals were reground to 20 thou. – main bearings untouched standard size. The big-end shells are lead bronze. These were reworked by honing from undersize shells to fit the problematic long nose crank. Lead bronze shells have been used on racing engines in the past but are hard on a crankshaft. For this reason a pre-oiling system has been fitted to this engine to pressure charge the lube system when starting, to extend the bearing life*, this provides an initial 40 psi oil to the system at start-up. The engine idles (cold) at around 42 p. s. i (these pressures appear to be controlled by the relief-valve spring-setting) and easily reaches 50+ p. s. i. when lightly revved. The engine has been run for around two hours using a temporary closed circuit cooling system. One of the big-end bearings was inspected at 1 ½ hours – the bearing surface honing appearing completely untouched from installation.

(* Note: a rule of thumb is that about 80% of engine wear occurs on start-up, hence the pre-oiler.)

The engine has a bespoke alternator bracket to take the later VW Beetle and T2 van, 12-volt alternator. These alternators are available quite cheaply and are typically rated at 55 amps. This type was chosen to provide adequate charging at the lower revs of a Flathead V8 engine working through an overdrive unit. The alternator fitted is a non-working slave used to prove the new belt system geometry and is not internally complete. It will need replacing.

The engine starts easily, produces excellent oil pressure and has a great exhaust note with the expansion boxes shown (and is surprisingly refined when idling). The flywheel was reworked from a standard Flathead flywheel to take a new 10” diameter 3. 4 - 3. 8 litre Jaguar MkII clutch cover and plate (violet pressure plate springs). A unique bell-housing was designed, a pattern made, and a prototype part cast in LM25 aluminium and machined to close tolerances for this application. The clutch, gearbox and overdrive are all comfortably capable of transmitting the Flathead torque. The flywheel was reduced in weight from 34 lbs to the 32 pounds specified by Ford for a four-speed gearbox when used with this engine. The gearbox appears to be virtually unused* and came from long-term storage with a Jaguar specialist. The overdrive is in working condition. The gear ratios are well matched to the 85 – 90 horse-power Flathead with 3. 38:1 on first. Second, third and fourth (straight through) are typical of those found in the BorgWarner/ Tremec T5 box. The overdrive gear is probably better suited to the Flathead at 0. 778:1, than the T5 fifth gear, (the T5 is, typically, very ‘tall; at around 0. 68:1). The carburettor is an unworn Holley 885 DD. (this is the military version of the 885 carb and has an armoured malleable iron housing) a very good carburettor with most spares still available from Holley. The 885 air intake is horizontally aligned rearward, this allows a much lower bonnet line to be achieved than the usual extremely tall top-fed Ford or Holley carburettor (particularly so when topped by a standard air filter). The civilian version of the 885 Holley was fitted to later Mercury Cars which were fitted with the 24 stud Flathead.

* The gearbox appears to have been removed from a vehicle due to a leak between the overdrive and gearbox (a common problem with these overdrive boxes). This leak was discovered on initial engine testing and quickly drained oil from the o/ d oil pressure accumulator (hence no o/ d function). The problem has been mostly rectified with the result that the assembly retains its oil and therefore works fine. Residual leakage remains but is considered manageable.

The engine has been carefully run for a total of about 120 minutes (at steady speeds) and has been brought up to a maximum of about 160 degrees Fahrenheit using a closed cooling circuit holding about 2 gallons of water per side (no radiator). This has allowed a maximum of about 15-20 minutes running at a time. This is not long enough for the oil to become hot (hand warm only) at which point the oil pressure on tick-over is 40+ psi. Lifting the revs to about 1200 rpm gives 50+ psi. The instruction book for the V8 industrial engine states that the oil pressure should be ‘30 lbs per sq inch under normal operating conditions’. Low-cost semi-synthetic oil was used for the initial running and changed after about the first two minutes, then again at about one hour. This flushing has been done to clear mineral oil residue and to clear any grime remaining in the inaccessible nooks and crannies of the engine. A final fill of Mobiloil 5W-40 has just been completed.

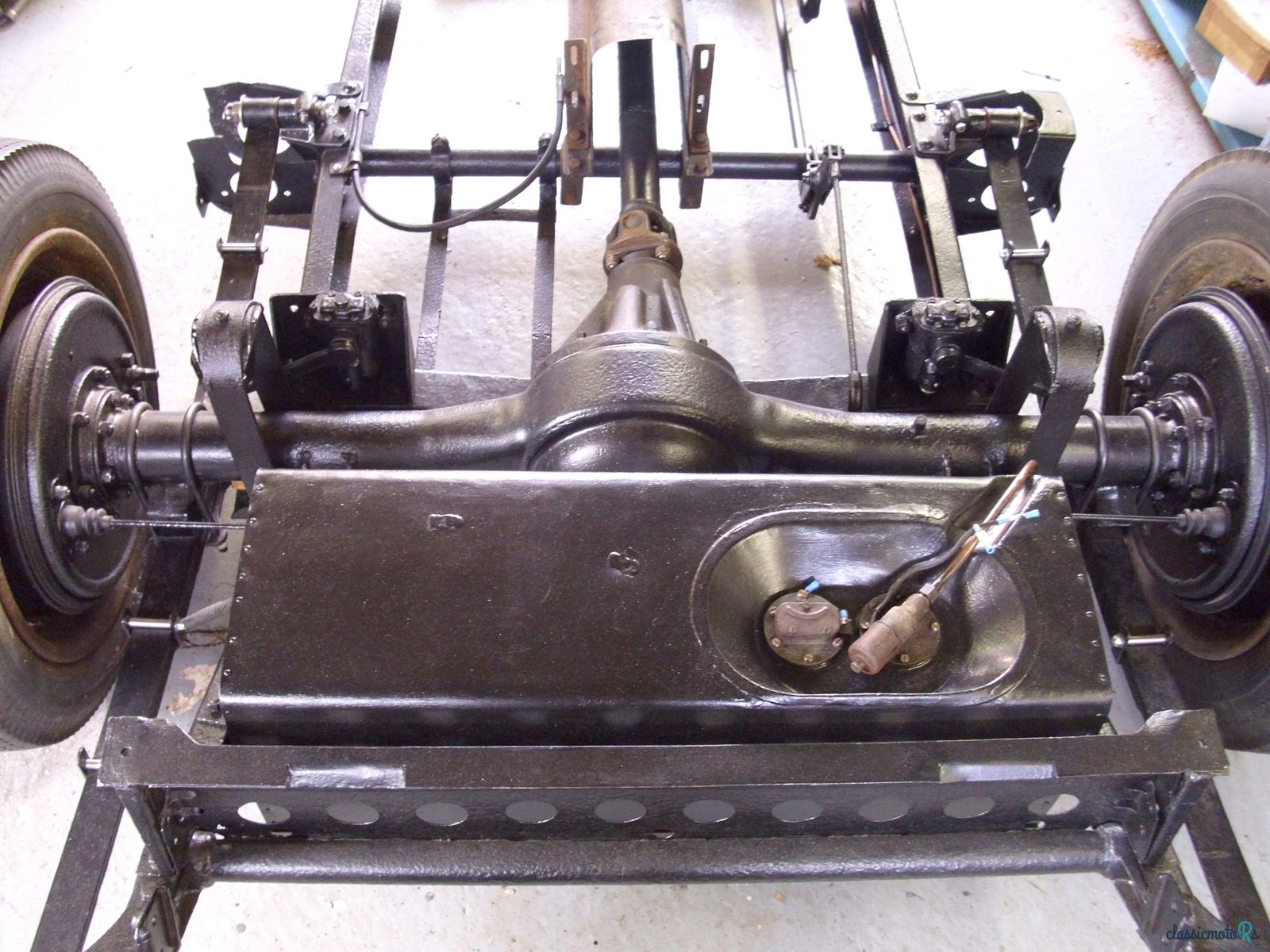

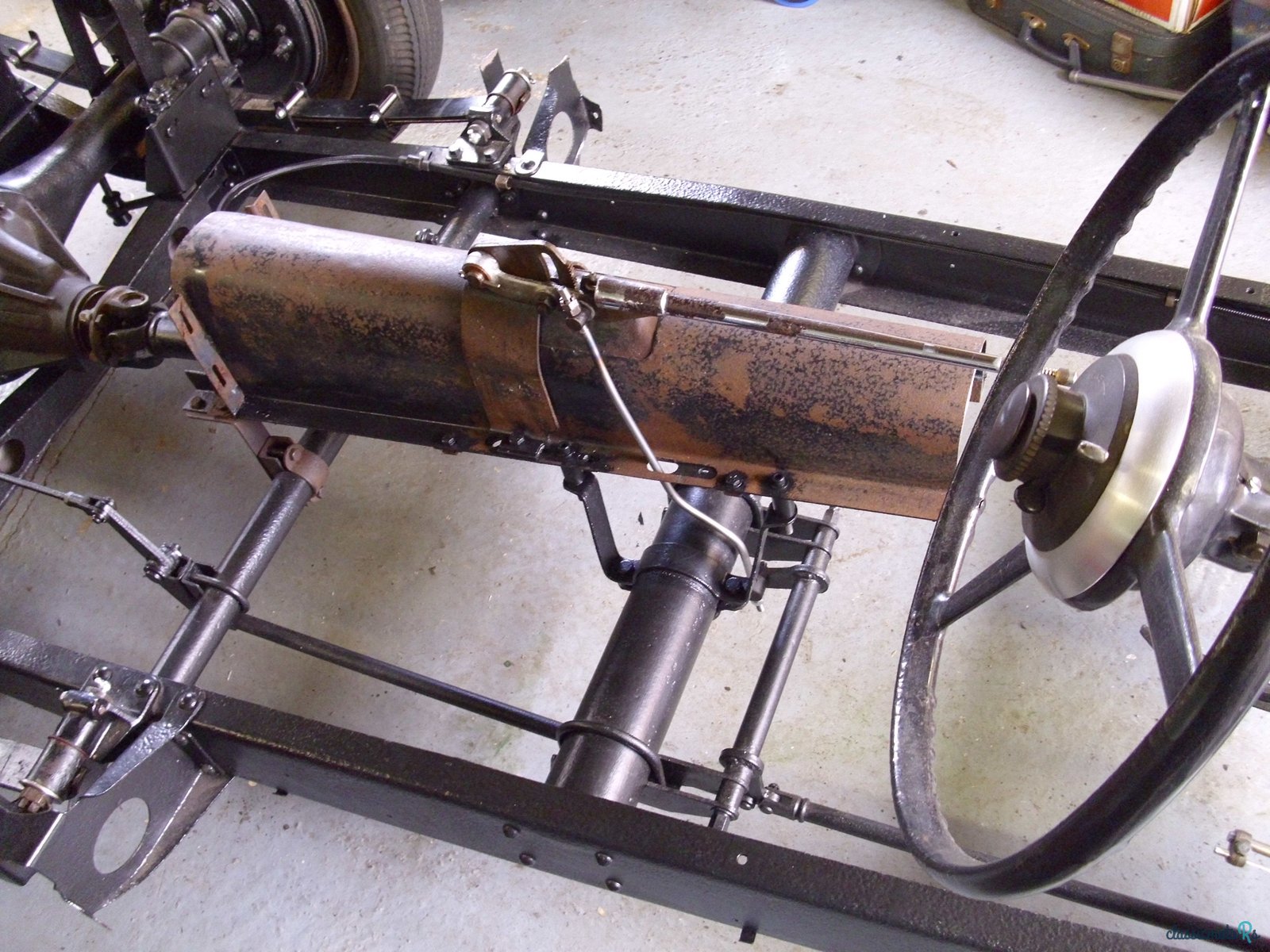

The P2 chassis was fundamentally sound without excessive corrosion and has been blast cleaned and two-pack epoxy coated. A couple of coats of industrial quality brushing chassis-black were put over the top of the two-pack to give a correct period look and provide an easily maintained paint finish. Various repairs were necessary where ancient accident damage was discovered and where poor initial build quality was evident. The chassis is actually of 1940 build (earlier than the registration details) this was only known after sandblasting when the original serial was revealed. The vehicle identity is inherent in the registration, the VIN plate and bulkhead. The road springs were dismantled cleaned up and some leaves replaced. The rear springs have also had one leaf removed; a normal requirement with the P2 chassis when given a lightweight body. It is possible that the front springs will require an additional leaf or spring assister due to the greater weight of the V8 powertrain installation. The chassis has not been modified in any way* and retains the standard rod operated 12” diameter drum brakes. A standard Rover steering column and front and rear axles have been retained (one of the two columns available is from a sports model P2 and 2. 25” longer than standard – this is the installed part). The front axle has replacement king-pins and bushes; the wheel bearings have been replaced on both sides and use a shimmed spacer for bearing adjustment, as found on earlier Rover types. The rear axle has been fitted with a brand-new Classic Range Rover differential of 3. 54:1. This will provide correct overall gearing for the V8. A shortened Classic Range Rover prop shaft is mounted and will accept the engine assembly directly. The brake shoes have been relined and two drums changed with skimmed replacements. Various parts have been replaced by better used parts. The steering box will require an adaptor mount to shift it both back and down for clearance and function. This can be a simple laser-cut part of 10mm thick plate (from the Autocad file noted above).

The rolling chassis has been built up over the last few months (summer 2021) as follows:

• Complete brake linkage restored, painted and installed with pedal lever.

• Fuel tank, leaded repairs and paint, new rubber mountings, fuel sender and reserve solenoid both fitted and working.

• Fuel line installed.

• Battery cable restored and installed.

• Tunnel installed with handbrake and new handbrake link.

• Clutch mechanism with cable and pedal lever.

• Set of four Armstrong piston-dampers with links; dampers restored with new seals and core plugs. Dampers working and presently leak-free (subject to trials)

• Rear anti-roll bar complete. Front Anti-roll bar links installed (see also note below).

• Drive shaft shortened and installed.

The chassis presently sits on ancient mismatched tyres but a set of four NOS Goodyear tyres is available with the package (see photograph). These tyres are 4. 75/ 5. 00 x 17. 00 and are perfectly matched to the powertrain installation. (Note that the tyres are OLD stock, are in generally excellent condition and still have the waxy surface feel of new tyres. They are suitable for an initial build and low-ish motorway speeds (e. g. up to 70mph). Either of two of the present fitted tyres could provide a get you home spare. The tyres supplied will serve well for sensible use and the buyer is advised to recognise the safety limitations applicable to this case.

* This is so that the V5 document description is still valid. The standard chassis, when fitted with a new body that can legally be described as a ‘saloon’ should only require informing DVLA of the engine change and body colour change for registration purposes (buyer to confirm). A saloon must have rear seating and a partition between the passenger compartment and luggage space (boot). I intended a tight two-plus-two arrangement with a two door body and boot as styling drawing, to meet this criterion. Other body arrangements are feasible, given respect of DVLA registration requirements. Two engine photo dates are wrong - engine photos taken early 2021; all chassis photographs were taken recently.

Various period instruments are included with the package including a serviced Jaguar speedometer (including new cable) which is compatible with the overdrive gearbox/ differential/ tyres and should read correctly. Oil pressure, water temperature, ignition/ starter switch are included. The steering wheel is an early post-war P2 type and a centre stator arrangement (horn) has been assembled using pre-war parts to give an appropriate look (cord steering-wheel binding intended). This will need further finishing work. A P2 upper (body-side) fuel filler-neck and lockable cap is included.

E-mail for further details.

Other parts included:

Firewall with VIN plate (also some other body panels for use as stock material from which the styled radiator shroud (body front-end) can be assembled.) Pair stainless steel expansion boxes (very effective) plus half a dozen m. s. exhaust bends (presently serving as cooling circuit parts).

Spare parts:

Pair of new Paul Beck uprated water pumps - these are the intended fit pumps.

Spare cylinder block. This block has had the liners removed. It could be reused either by installing new liners or by the use of 3 3/ 16” (239 cubic inch) pistons directly in the bores. This would increase power output by about 8% for a given shaft speed. The valve seats will require re-cutting (I can supply a cutter) and new valves, springs etc. obtained. Two broken off studs will require careful removal. The block is in good order and appears entirely crack free. A replacement crankshaft would be required for this spare block.

Pair of good cylinder heads.

Spare Flywheel (with Lucas style starter ring as fitted to the Ford Pilot)

Spare good oil pump.

Good camshaft (requires replacement fibre gear)

8 pistons and rods + five decent used cylinder sleeves.

Lucas distributor with flawless cap (rare)

Spare standard steering column.

Original 4. 4:1 diff.

Chassis/ engine work to do:

Air intake plenum/ filter.

Replace alternator.

Adjust clutch levers.

Steering column plate

Engine support structure (design available)

Radiator (obtain and install).

Make up clutch operating lever (for cable operation at engine end - design available).

2” fuel filler elbow to be fitted to fuel tank (can be installed with JB Weld or similar)

(Sizing and guidance available for some of the design work)

Wheel balance requirement: Because of the large brake drums on the P2 (which were poorly balanced from new) both wheel and brake drum assemblies must be balanced on these chassis. It is possible to statically balance each wheel/ drum as a single assembly, if so the wheel location and orientation will subsequently require strict observation when removing or replacing a wheel.

The engine is mounted on a makeshift wheeled trolley so can be moved and loaded easily onto a low transporter or trailer with suitable ramps. The chassis is easily rolled and again allows easy loading to a suitable vehicle or trailer.

The engine can be heard running on collection if required. Payment must be made on or before collection. No guarantee is given or implied for any of the package and no return will be accepted after sale under any circumstances

Project for Sale:

This project consists of what is believed to be a unique powertrain assembly - a 221 cubic inch Ford V8 flathead engine mated to a Jaguar 3. 4 litre overdrive gearbox (circa 1965) - together with a Rover P2 chassis. The chassis is on the DVLA database and the correct VIN plate is available with its original bulkhead. An AutoCad design file of fundamental layout etc is available to those with access to the software. A laser cutting file is available for engine installation, brake/ clutch pedal and other components. A4 prints could also be supplied to assist. A casting pattern for the unique bell-housing is available with the package. The design and engineering work has been carried out by an ex automotive engineer.

The intention has been to provide a character vehicle with the ability to cruise at moderate motorway speeds whilst providing acceptable fuel economy and reasonable refinement for touring. These attributes can be expected from the high-torque eight-cylinder engine, with power delivered through, what is effectively, a five-speed gearbox. See vehicle concept sketches.

The engine was built to prove out the gearbox installation, for vehicle build and initial use. The original surface patination has been deliberately retained. The engine is assembled from the better parts of two WWII fire pump power units (built at the Dagenham factory). The engine model is typical of the 1937 – 1942 American design but with the earlier 21 stud head and the non-standard big-end journals (as used later in the Ford Pilot). Cylinder liners were standard in these engines and this particular engine has hard-chromed upper piston rings which hardly wear the carbon-rich liners. The pistons have light wear. Crankshaft big-end journals were reground to 20 thou. – main bearings untouched standard size. The big-end shells are lead bronze. These were reworked by honing from undersize shells to fit the problematic long nose crank. Lead bronze shells have been used on racing engines in the past but are hard on a crankshaft. For this reason a pre-oiling system has been fitted to this engine to pressure charge the lube system when starting, to extend the bearing life*, this provides an initial 40 psi oil to the system at start-up. The engine idles (cold) at around 42 p. s. i (these pressures appear to be controlled by the relief-valve spring-setting) and easily reaches 50+ p. s. i. when lightly revved. The engine has been run for around two hours using a temporary closed circuit cooling system. One of the big-end bearings was inspected at 1 ½ hours – the bearing surface honing appearing completely untouched from installation.

(* Note: a rule of thumb is that about 80% of engine wear occurs on start-up, hence the pre-oiler.)

The engine has a bespoke alternator bracket to take the later VW Beetle and T2 van, 12-volt alternator. These alternators are available quite cheaply and are typically rated at 55 amps. This type was chosen to provide adequate charging at the lower revs of a Flathead V8 engine working through an overdrive unit. The alternator fitted is a non-working slave used to prove the new belt system geometry and is not internally complete. It will need replacing.

The engine starts easily, produces excellent oil pressure and has a great exhaust note with the expansion boxes shown (and is surprisingly refined when idling). The flywheel was reworked from a standard Flathead flywheel to take a new 10” diameter 3. 4 - 3. 8 litre Jaguar MkII clutch cover and plate (violet pressure plate springs). A unique bell-housing was designed, a pattern made, and a prototype part cast in LM25 aluminium and machined to close tolerances for this application. The clutch, gearbox and overdrive are all comfortably capable of transmitting the Flathead torque. The flywheel was reduced in weight from 34 lbs to the 32 pounds specified by Ford for a four-speed gearbox when used with this engine. The gearbox appears to be virtually unused* and came from long-term storage with a Jaguar specialist. The overdrive is in working condition. The gear ratios are well matched to the 85 – 90 horse-power Flathead with 3. 38:1 on first. Second, third and fourth (straight through) are typical of those found in the BorgWarner/ Tremec T5 box. The overdrive gear is probably better suited to the Flathead at 0. 778:1, than the T5 fifth gear, (the T5 is, typically, very ‘tall; at around 0. 68:1). The carburettor is an unworn Holley 885 DD. (this is the military version of the 885 carb and has an armoured malleable iron housing) a very good carburettor with most spares still available from Holley. The 885 air intake is horizontally aligned rearward, this allows a much lower bonnet line to be achieved than the usual extremely tall top-fed Ford or Holley carburettor (particularly so when topped by a standard air filter). The civilian version of the 885 Holley was fitted to later Mercury Cars which were fitted with the 24 stud Flathead.

* The gearbox appears to have been removed from a vehicle due to a leak between the overdrive and gearbox (a common problem with these overdrive boxes). This leak was discovered on initial engine testing and quickly drained oil from the o/ d oil pressure accumulator (hence no o/ d function). The problem has been mostly rectified with the result that the assembly retains its oil and therefore works fine. Residual leakage remains but is considered manageable.

The engine has been carefully run for a total of about 120 minutes (at steady speeds) and has been brought up to a maximum of about 160 degrees Fahrenheit using a closed cooling circuit holding about 2 gallons of water per side (no radiator). This has allowed a maximum of about 15-20 minutes running at a time. This is not long enough for the oil to become hot (hand warm only) at which point the oil pressure on tick-over is 40+ psi. Lifting the revs to about 1200 rpm gives 50+ psi. The instruction book for the V8 industrial engine states that the oil pressure should be ‘30 lbs per sq inch under normal operating conditions’. Low-cost semi-synthetic oil was used for the initial running and changed after about the first two minutes, then again at about one hour. This flushing has been done to clear mineral oil residue and to clear any grime remaining in the inaccessible nooks and crannies of the engine. A final fill of Mobiloil 5W-40 has just been completed.

The P2 chassis was fundamentally sound without excessive corrosion and has been blast cleaned and two-pack epoxy coated. A couple of coats of industrial quality brushing chassis-black were put over the top of the two-pack to give a correct period look and provide an easily maintained paint finish. Various repairs were necessary where ancient accident damage was discovered and where poor initial build quality was evident. The chassis is actually of 1940 build (earlier than the registration details) this was only known after sandblasting when the original serial was revealed. The vehicle identity is inherent in the registration, the VIN plate and bulkhead. The road springs were dismantled cleaned up and some leaves replaced. The rear springs have also had one leaf removed; a normal requirement with the P2 chassis when given a lightweight body. It is possible that the front springs will require an additional leaf or spring assister due to the greater weight of the V8 powertrain installation. The chassis has not been modified in any way* and retains the standard rod operated 12” diameter drum brakes. A standard Rover steering column and front and rear axles have been retained (one of the two columns available is from a sports model P2 and 2. 25” longer than standard – this is the installed part). The front axle has replacement king-pins and bushes; the wheel bearings have been replaced on both sides and use a shimmed spacer for bearing adjustment, as found on earlier Rover types. The rear axle has been fitted with a brand-new Classic Range Rover differential of 3. 54:1. This will provide correct overall gearing for the V8. A shortened Classic Range Rover prop shaft is mounted and will accept the engine assembly directly. The brake shoes have been relined and two drums changed with skimmed replacements. Various parts have been replaced by better used parts. The steering box will require an adaptor mount to shift it both back and down for clearance and function. This can be a simple laser-cut part of 10mm thick plate (from the Autocad file noted above).

The rolling chassis has been built up over the last few months (summer 2021) as follows:

• Complete brake linkage restored, painted and installed with pedal lever.

• Fuel tank, leaded repairs and paint, new rubber mountings, fuel sender and reserve solenoid both fitted and working.

• Fuel line installed.

• Battery cable restored and installed.

• Tunnel installed with handbrake and new handbrake link.

• Clutch mechanism with cable and pedal lever.

• Set of four Armstrong piston-dampers with links; dampers restored with new seals and core plugs. Dampers working and presently leak-free (subject to trials)

• Rear anti-roll bar complete. Front Anti-roll bar links installed (see also note below).

• Drive shaft shortened and installed.

The chassis presently sits on ancient mismatched tyres but a set of four NOS Goodyear tyres is available with the package (see photograph). These tyres are 4. 75/ 5. 00 x 17. 00 and are perfectly matched to the powertrain installation. (Note that the tyres are OLD stock, are in generally excellent condition and still have the waxy surface feel of new tyres. They are suitable for an initial build and low-ish motorway speeds (e. g. up to 70mph). Either of two of the present fitted tyres could provide a get you home spare. The tyres supplied will serve well for sensible use and the buyer is advised to recognise the safety limitations applicable to this case.

* This is so that the V5 document description is still valid. The standard chassis, when fitted with a new body that can legally be described as a ‘saloon’ should only require informing DVLA of the engine change and body colour change for registration purposes (buyer to confirm). A saloon must have rear seating and a partition between the passenger compartment and luggage space (boot). I intended a tight two-plus-two arrangement with a two door body and boot as styling drawing, to meet this criterion. Other body arrangements are feasible, given respect of DVLA registration requirements. Two engine photo dates are wrong - engine photos taken early 2021; all chassis photographs were taken recently.

Various period instruments are included with the package including a serviced Jaguar speedometer (including new cable) which is compatible with the overdrive gearbox/ differential/ tyres and should read correctly. Oil pressure, water temperature, ignition/ starter switch are included. The steering wheel is an early post-war P2 type and a centre stator arrangement (horn) has been assembled using pre-war parts to give an appropriate look (cord steering-wheel binding intended). This will need further finishing work. A P2 upper (body-side) fuel filler-neck and lockable cap is included.

E-mail for further details.

Other parts included:

Firewall with VIN plate (also some other body panels for use as stock material from which the styled radiator shroud (body front-end) can be assembled.) Pair stainless steel expansion boxes (very effective) plus half a dozen m. s. exhaust bends (presently serving as cooling circuit parts).

Spare parts:

Pair of new Paul Beck uprated water pumps - these are the intended fit pumps.

Spare cylinder block. This block has had the liners removed. It could be reused either by installing new liners or by the use of 3 3/ 16” (239 cubic inch) pistons directly in the bores. This would increase power output by about 8% for a given shaft speed. The valve seats will require re-cutting (I can supply a cutter) and new valves, springs etc. obtained. Two broken off studs will require careful removal. The block is in good order and appears entirely crack free. A replacement crankshaft would be required for this spare block.

Pair of good cylinder heads.

Spare Flywheel (with Lucas style starter ring as fitted to the Ford Pilot)

Spare good oil pump.

Good camshaft (requires replacement fibre gear)

8 pistons and rods + five decent used cylinder sleeves.

Lucas distributor with flawless cap (rare)

Spare standard steering column.

Original 4. 4:1 diff.

Chassis/ engine work to do:

Air intake plenum/ filter.

Replace alternator.

Adjust clutch levers.

Steering column plate

Engine support structure (design available)

Radiator (obtain and install).

Make up clutch operating lever (for cable operation at engine end - design available).

2” fuel filler elbow to be fitted to fuel tank (can be installed with JB Weld or similar)

(Sizing and guidance available for some of the design work)

Wheel balance requirement: Because of the large brake drums on the P2 (which were poorly balanced from new) both wheel and brake drum assemblies must be balanced on these chassis. It is possible to statically balance each wheel/ drum as a single assembly, if so the wheel location and orientation will subsequently require strict observation when removing or replacing a wheel.

The engine is mounted on a makeshift wheeled trolley so can be moved and loaded easily onto a low transporter or trailer with suitable ramps. The chassis is easily rolled and again allows easy loading to a suitable vehicle or trailer.

The engine can be heard running on collection if required. Payment must be made on or before collection. No guarantee is given or implied for any of the package and no return will be accepted after sale under any circumstances